Korohereza ibinyabiziga nintego ihuriweho ninganda zimodoka ku isi. Kongera ikoreshwa ryibikoresho bya aluminiyumu mu bikoresho byimodoka nicyerekezo cyiterambere ryibinyabiziga bigezweho. 6082 aluminiyumu ni ubushyuhe bushobora kuvurwa nubushyuhe, imbaraga za aluminiyumu zifite imbaraga ziciriritse, imiterere ihebuje, gusudira, kurwanya umunaniro, no kurwanya ruswa. Iyi mavuta irashobora gukururwa mu miyoboro, mu nkoni, no mu mwirondoro, kandi ikoreshwa cyane mu bice by'imodoka, gusudira ibice byubatswe, ubwikorezi, n'inganda zubaka.

Kugeza ubu, hari ubushakashatsi buke kuri 6082 ya aluminiyumu ikoreshwa mu modoka nshya z’ingufu mu Bushinwa. Kubwibyo, ubu bushakashatsi bwubushakashatsi bukora iperereza ku ngaruka za 6082 ya aluminiyumu ya aluminiyumu igizwe n'ibipimo, ibipimo byo gukuramo ibicuruzwa, uburyo bwo kuzimya, n'ibindi, ku mikorere ya profili ya alloy na microstructure. Ubu bushakashatsi bugamije kunoza imiterere ya alloy hamwe nibipimo byo gutunganya kugirango habeho ibikoresho 6082 bya aluminium alloy ibereye ibinyabiziga bishya byingufu.

1. Ibikoresho by'ibizamini hamwe nuburyo

Ikigeragezo cyibikorwa: Ikigereranyo cya Alloy igereranya - Ingot gushonga - Ingot homogenisation - Ingot ibona mumpapuro - Gukuramo imyirondoro - Kumurongo wo kuzimya imyirondoro - Gusaza kwa artile - Gutegura ibizamini.

1.1 Gutegura Ingot

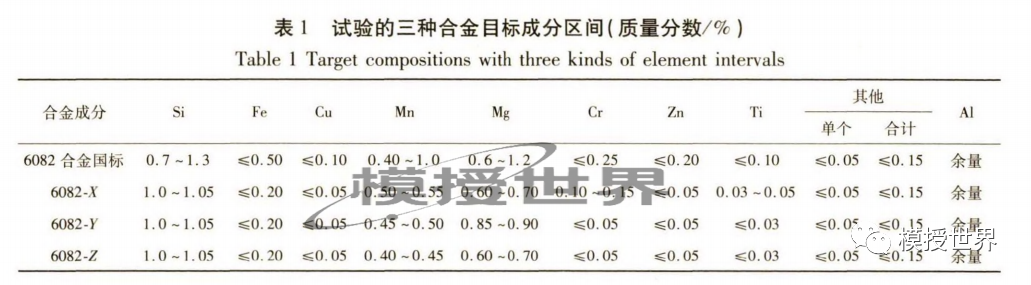

Mu rwego mpuzamahanga rwa 6082 ya aluminiyumu ivanze, ibice bitatu byatoranijwe hamwe nurwego ruciriritse, byanditseho 6082- / 6082 ″, 6082-Z, hamwe nibintu bimwe bya Si. Ibintu bya Mg, y> z; Ibigize Mn, x> y> z; Cr, Ibigize Ti, x> y = z. Indangagaciro zihariye za aliyumu zigaragara mu mbonerahamwe ya 1. Gutera ingot byakozwe hakoreshejwe uburyo bwo gukomeza gukonjesha amazi-gukonjesha, hanyuma hakurikiraho kuvura homogenisation. Ibikoresho byose uko ari bitatu byahujwe hakoreshejwe sisitemu yashyizweho n’uruganda kuri 560 ° C mu masaha 2 hamwe no gukonjesha amazi.

1.2 Gukuramo imyirondoro

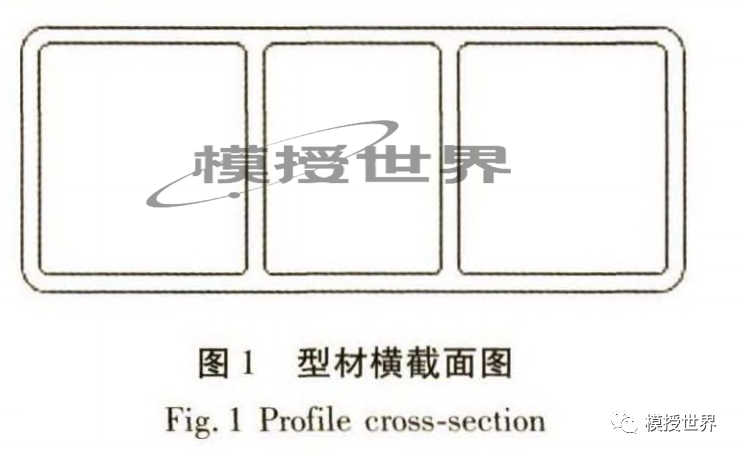

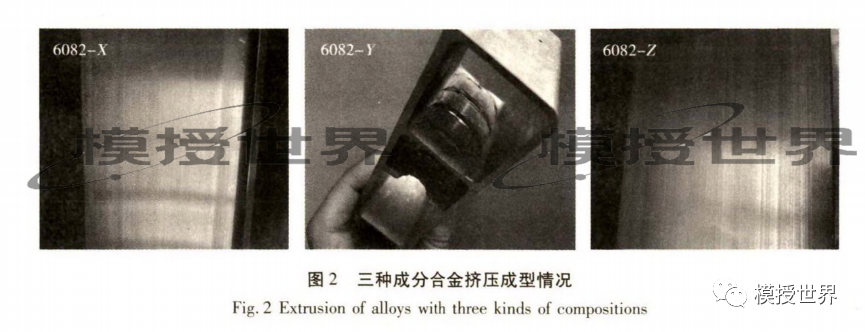

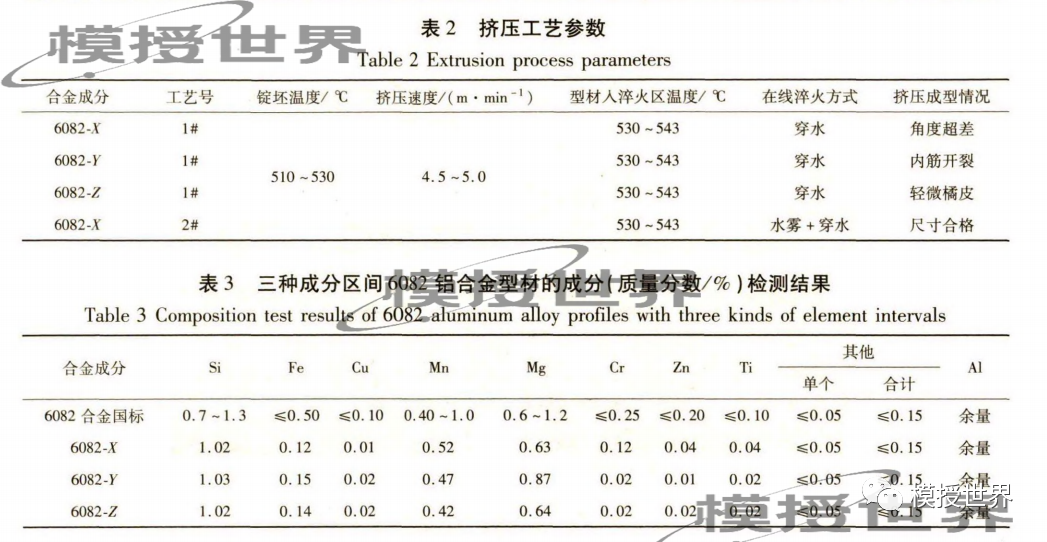

Ibipimo byo gukuramo ibicuruzwa byahinduwe uko bikwiye ubushyuhe bwa billet no kuzimya igipimo cyo gukonjesha. Igice cyambukiranya imyirondoro cyerekanwe cyerekanwe ku gishushanyo cya 1. Ibipimo byerekana uburyo bwo gusohora byerekanwe mu mbonerahamwe ya 2. Imiterere yimiterere yimyirondoro yasohotse irerekanwa ku gishushanyo cya 2.

2.Ibisubizo by'ibizamini n'isesengura

Imiterere yihariye ya chimique ya 6082 ya aluminium alloy imyirondoro iri mubice bitatu bigize ibice byagenwe hakoreshejwe uburyo bwo gusoma bwa ARL bwo mu Busuwisi, nkuko bigaragara mu mbonerahamwe ya 3.

2.1 Kwipimisha

Kugereranya, hasuzumwe imikorere yuburyo butatu bugizwe na profili hamwe nuburyo butandukanye bwo kuzimya, ibipimo bimwe byo gukuramo, hamwe nubusaza byasuzumwe.

2.1.1 Imikorere ya mashini

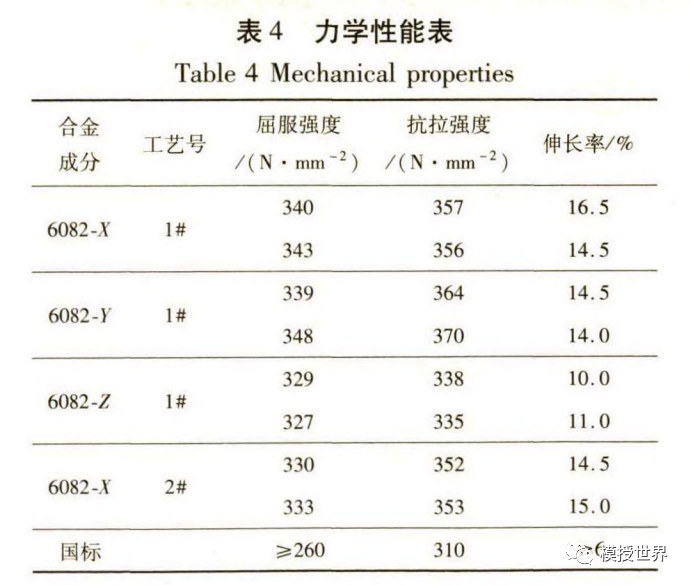

Nyuma yo gusaza ibihimbano kuri 175 ° C mumasaha 8, ingero zisanzwe zavanywe mu cyerekezo cyo gukuramo imyirondoro kugirango zipimishe cyane hakoreshejwe imashini yipimisha Shimadzu AG-X100. Imikorere ya mashini nyuma yo gusaza kwubukorikori kubintu bitandukanye nuburyo bwo kuzimya bigaragara mu mbonerahamwe ya 4.

Kuva ku mbonerahamwe ya 4, birashobora kugaragara ko imikorere yubukorikori bwa profil yose irenze indangagaciro zigihugu. Umwirondoro wakozwe kuva 6082-Z alloy bilet yari ifite uburebure buke nyuma yo kuvunika. Umwirondoro wakozwe kuva 6082-7 alloy bilet yari ifite imikorere yubukorikori buhanitse. 6082-X ivanga imyirondoro, hamwe nuburyo butandukanye bwo gukemura, yerekanye imikorere ihanitse hamwe nuburyo bwo kuzimya byihuse.

2.1.2

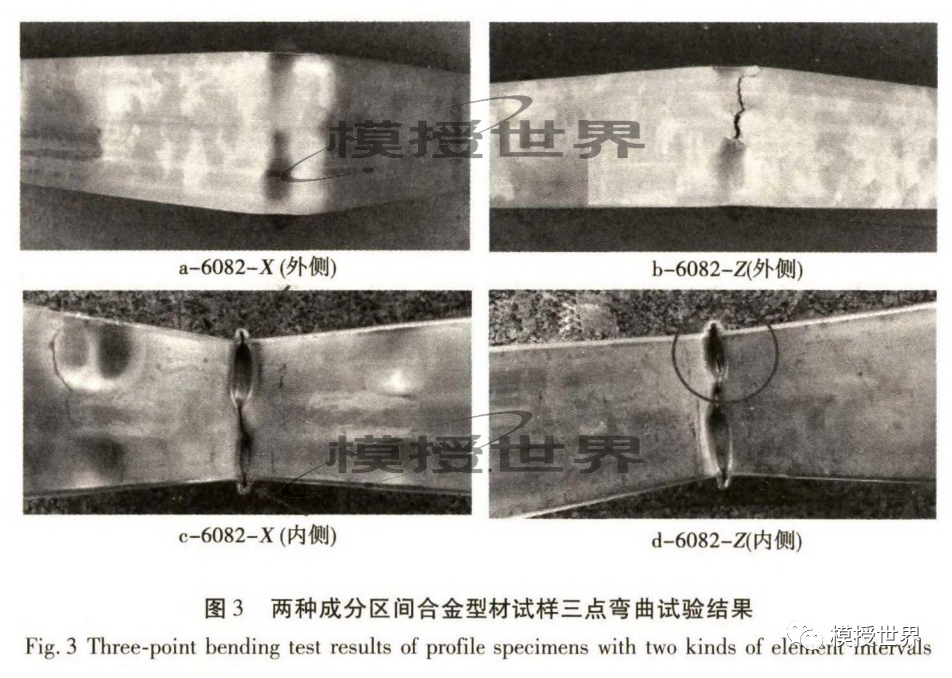

Hifashishijwe imashini yipimisha kuri elegitoronike, ibizamini bitatu byunamye byakorewe ku ngero, kandi ibisubizo byunamye byerekanwe ku gishushanyo cya 3. Igishushanyo cya 3 cyerekana ko ibicuruzwa biva mu mafranga 6082-Z bivanze byari bifite igishishwa gikomeye cya orange hejuru kandi kigacika inyuma yicyitegererezo. Ibicuruzwa byakozwe kuva kuri 6082-X byitwa bilet byari bifite imikorere myiza yo kunama, hejuru yoroheje idafite igishishwa cya orange, kandi uduce duto gusa kumyanya igarukira kumiterere ya geometrike inyuma yicyitegererezo.

2.1.3 Igenzura ryinshi

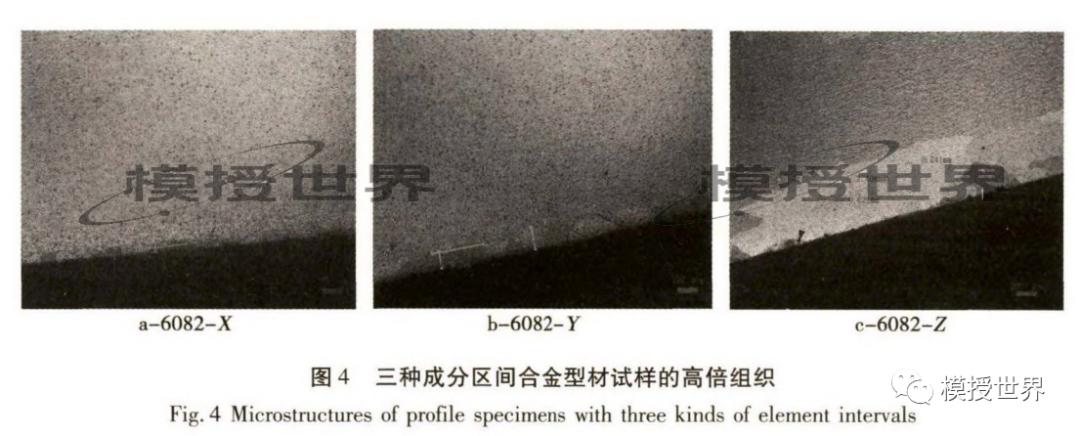

Ingero zagaragaye munsi ya Carl Zeiss AX10 optique ya microscope yo gusesengura microstructure. Isesengura rya microstructure ibisubizo kubice bitatu bigize ibipimo byerekana ibishushanyo mbonera byerekanwe ku gishushanyo cya 4. Igishushanyo cya 4 cyerekana ko ingano y’ibicuruzwa byakozwe mu nkoni 6082-X hamwe na fagitire 6082-K byari bisa, bifite ingano nziza cyane muri 6082-X ivanze ugereranije na 6082-y. Ibicuruzwa byakozwe kuva 6082-Z alloy bilet byari bifite ingano nini nini ya cortex nini cyane, ibyo bikaba byaratumaga byoroshye igishishwa cya orange hejuru kandi bigahuza ibyuma byimbere.

2.2 Isesengura ry'ibisubizo

Ukurikije ibisubizo byavuzwe haruguru, hashobora kwemezwa ko igishushanyo mbonera cya alloy igizwe ningaruka zigira ingaruka cyane kuri microstructure, imikorere, nuburyo bwo gukora imyirondoro yatanzwe. Ibintu byiyongereye bya Mg bigabanya plastike ivanze kandi biganisha kumeneka mugihe cyo gukuramo. Ibiri hejuru ya Mn, Cr, na Ti bigira ingaruka nziza mugutunganya microstructure, nayo igira ingaruka nziza kumiterere yubuso, imikorere yunamye, nibikorwa rusange.

3.Umwanzuro

Mg element igira ingaruka zikomeye kumikorere ya 6082 ya aluminium. Kwiyongera kwa Mg kugabanya plastike ivanze kandi biganisha kumeneka mugihe cyo gukuramo.

Mn, Cr, na Ti bigira ingaruka nziza mugutunganya microstructure, biganisha ku kuzamura ubwiza bwubuso no kugoreka ibicuruzwa biva hanze.

Ubukonje butandukanye bwo gukonjesha bugira ingaruka zigaragara kumikorere ya 6082 ya aluminium alloy profil. Kugirango ukoreshe ibinyabiziga, gukoresha uburyo bwo kuzimya ibicu byamazi bikurikirwa no gukonjesha amazi bitanga imikorere myiza yubukanishi kandi bikerekana imiterere yumwirondoro hamwe nukuri.

Byahinduwe na Gicurasi Jiang wo muri MAT Aluminium

Igihe cyo kohereza: Werurwe-26-2024