6063 ya aluminiyumu ni iy'umuti muto wa Al-Mg-Si ukurikirana ubushyuhe-bushobora gukoreshwa na aluminiyumu. Ifite uburyo bwiza bwo gukuramo ibicuruzwa, kurwanya ruswa neza hamwe nubukanishi bwuzuye. Irakoreshwa kandi cyane mu nganda z’imodoka kubera amabara ya okiside yoroshye. Hamwe no kwihuta kwimodoka zoroheje, ikoreshwa ryibikoresho bya aluminiyumu 6063 biva mu nganda z’imodoka nabyo byiyongereye cyane.

Microstructure hamwe nibintu byibikoresho byakuweho bigira ingaruka ku ngaruka ziterwa n’umuvuduko ukabije, ubushyuhe bwo gukuramo no kugereranya. Muri byo, igipimo cyo gukuramo kigenwa ahanini nigitutu cyo gukuramo, gukora neza nibikoresho byo gukora. Iyo igipimo cyo gukuramo ari gito, ivugurura rya alloy riba rito kandi gutunganya microstructure ntabwo bigaragara; kongera igipimo cyo gukuramo gishobora gutunganya cyane ibinyampeke, gusenya icyiciro cya kabiri cyoroshye, kubona microstructure imwe, no kunoza imiterere yubukorikori.

6061 na 6063 aluminiyumu ya aluminiyumu ihura na dinamike yogusubiramo mugihe cyo gukuramo. Iyo ubushyuhe bwo gusohora buhoraho, uko igipimo cyo gukuramo cyiyongera, ingano yingano iragabanuka, icyiciro cyo gukomera kiratatana neza, kandi imbaraga zingana no kurambura amavuta byiyongera bikwiranye; icyakora, uko igipimo cyo gukuramo cyiyongera, imbaraga zo gusohora zisabwa mugikorwa cyo gukuramo nazo ziriyongera, bigatera ingaruka nyinshi zumuriro, bigatuma ubushyuhe bwimbere bwumuti bwiyongera, kandi nibikorwa byibicuruzwa bikagabanuka. Ubu bushakashatsi bwiga ku ngaruka zo kugereranya, cyane cyane igipimo kinini cyo gukuramo, kuri microstructure hamwe nubukanishi bwa 6063 aluminium.

1 Ibikoresho byubushakashatsi nuburyo

Ibikoresho byubushakashatsi ni 6063 ya aluminiyumu, kandi ibigize imiti byerekanwe mu mbonerahamwe ya 1. Ingano yumwimerere ya ingot ni mm 55 mm × 165 mm, kandi itunganyirizwa mu fagitire yo gukuramo ifite ubunini bwa mm 50 mm × 150 mm nyuma yo kuvura homogenisation kuri 560 ℃ kuri 6 h. Fagitire yashyutswe kugeza 470 ℃ kandi igakomeza gushyuha. Ubushyuhe bwo gushyushya ingunguru yo gukuramo ni 420 and, naho ubushyuhe bwo gushyushya ni 450 ℃. Iyo umuvuduko wo gusohora (umuvuduko wo kwimura umuvuduko) V = 5 mm / s idahindutse, hakozwe amatsinda 5 yikigereranyo cyo kugereranya ibicuruzwa biva hanze, naho ibipimo byo gukuramo R ni 17 (bihuye na diameter yo gupfa D = 12 mm), 25 (D = 10 mm), 39 (D = 8 mm), 69 (D = 6 mm), na 156 (D = 4 mm).

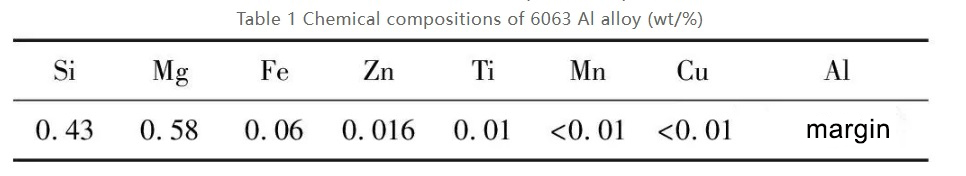

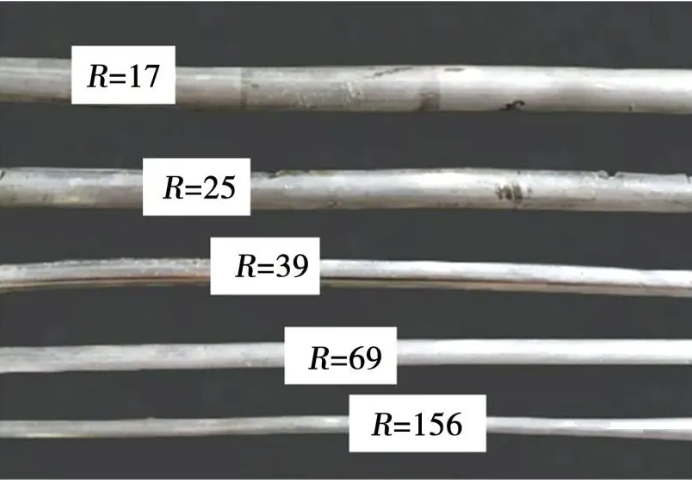

Imbonerahamwe 1 Ibigize imiti ya 6063 Al alloy (wt /%)

Nyuma yo gusya umucanga no gusya imashini, icyitegererezo cya metallografiya cyashyizwemo HF reagent hamwe nubunini bwa 40% kuri s 25, kandi imiterere yicyuma yagaragaye kuri microscope ya optique ya LEICA-5000. Icyitegererezo cyo gusesengura imiterere gifite ubunini bwa mm 10 × 10 mm cyaciwe hagati mu gice cyigihe kirekire cyinkoni yakuweho, hanyuma gusya no gukanika imashini byakozwe kugirango bikureho urwego rwo hejuru. Imibare ya pole ituzuye yindege eshatu za kirisiti {111}, {200}, na {220} z'icyitegererezo zapimwe na X′Pert Pro MRD X-ray itandukanya isesengura rya PANalytical Company, kandi amakuru yimiterere yatunganijwe kandi asesengurwa na X′Pert Data View na software ya X′Pert.

Urugero rwa tensile rwikigereranyo rwakuwe hagati rwagati, hanyuma ingero ya tensile yaciwe ku cyerekezo cyo gusohora nyuma yo gusohora. Ubunini bwapima bwari mm4 mm × 28 mm. Ikizamini cya tensile cyakozwe hifashishijwe imashini isuzuma ibikoresho bya SANS CMT5105 hamwe na tensile ya mm 2 / min. Impuzandengo yikigereranyo cyibintu bitatu bisanzwe byabazwe nkimiterere yimiterere yimashini. Imiterere ya morphologie yimiterere yikigereranyo yagaragaye hakoreshejwe microscope ya elegitoronike ntoya (Quanta 2000, FEI, USA).

2 Ibisubizo n'ibiganiro

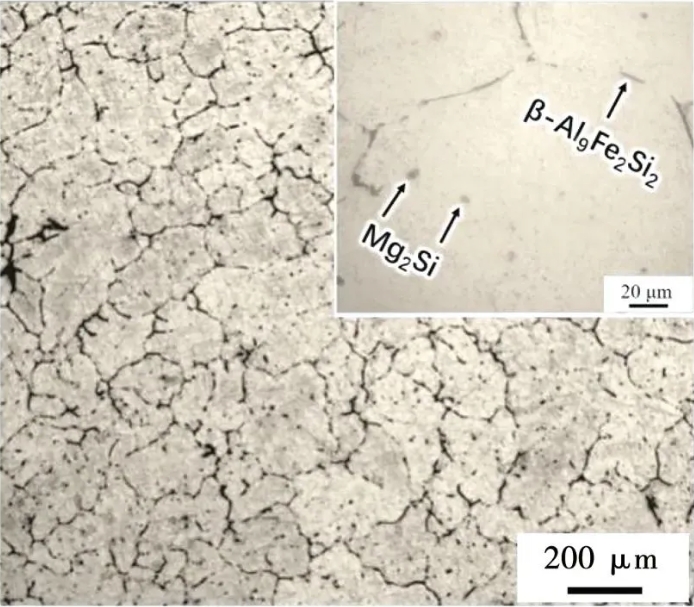

Igicapo 1 cerekana microstructure ya metallographic ya as-cast 6063 aluminiyumu mbere na nyuma yo kuvura homogenisation. Nkuko bigaragara ku gishushanyo 1a, ibinyampeke α-Al muri microstructure ya as-cast biratandukana mubunini, umubare munini wa reticular β-Al9Fe2Si2 ibyiciro byegeranya kumupaka wingano, kandi umubare munini wibyiciro bya Mg2Si bibaho imbere yintete. Nyuma yo gushiramo ingobyi kuri 560 ℃ kuri 6 h, icyiciro cya eutectic kitaringaniye hagati ya dendrite ya alloy dendrite cyashonze buhoro buhoro, ibintu bivangavanze bishonga muri matrise, microstructure yari imwe, kandi impuzandengo yingano yari hafi 125 mkm (Ishusho 1b).

Mbere yo guhuza ibitsina

Nyuma yo kuvura kimwe kuri 600 ° C mumasaha 6

Igishushanyo.1 Imiterere ya metero 6063 ya aluminiyumu mbere na nyuma yo kuvura homogenisation

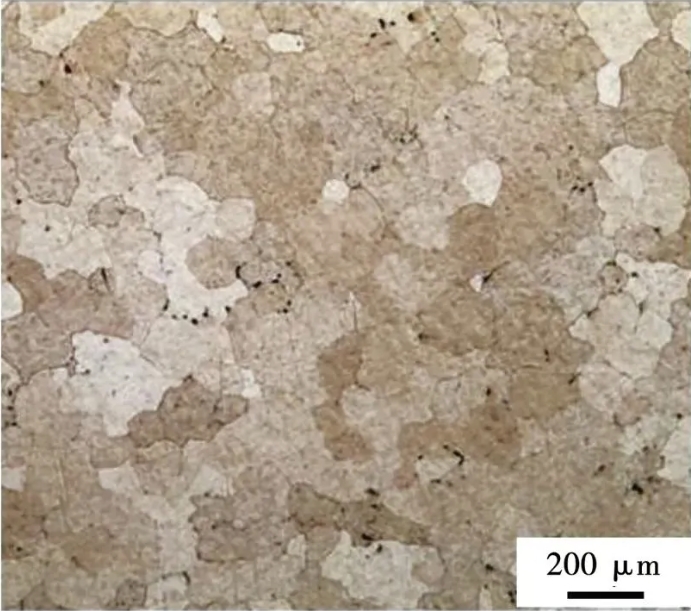

Igishushanyo cya 2 cyerekana isura ya 6063 aluminium alloy bar hamwe nibipimo bitandukanye byo gukuramo. Nkuko bigaragara ku gishushanyo cya 2, ubwiza bwubuso bwa 6063 aluminium alloy bar bwakuwe hamwe nibipimo bitandukanye byo gusohora nibyiza, cyane cyane iyo igipimo cyo gukuramo cyongerewe kugera kuri 156 (gihuye numuvuduko wo gusohora akabari kangana na 48 m / min), haracyariho inenge zo gukuramo nko gutobora no gutobora hejuru yumubyimba mwinshi kandi byerekana umuvuduko mwinshi wa aluminiyumu.

Igishushanyo.2 Kugaragara kwa 6063 aluminiyumu ya aliyumu ifite ibipimo bitandukanye byo gukuramo

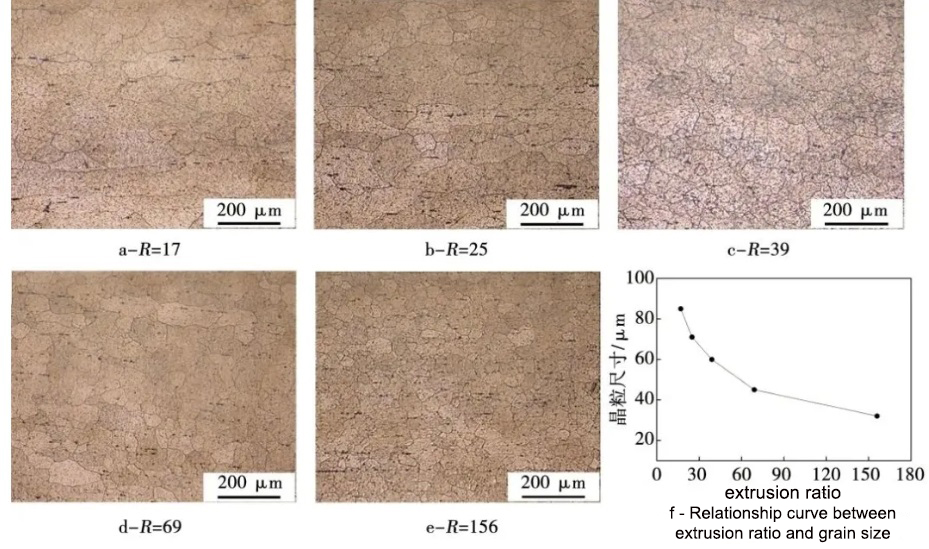

Igishushanyo cya 3 cyerekana microstructure ya metallographic igice cya longitudinal igice cya 6063 aluminium alloy bar hamwe nikigereranyo gitandukanye. Imiterere yintete yumubari hamwe nibipimo bitandukanye byo gukuramo byerekana impamyabumenyi zitandukanye zo kurambura cyangwa gutunganywa. Iyo igipimo cyo gukuramo ari 17, ibinyampeke byumwimerere birebire byerekanwe ku cyerekezo cyo gusohora, biherekejwe no gushiraho umubare muto w’ibinyampeke byongeye gushyirwaho, ariko ibinyampeke biracyari bike, bifite impuzandengo y’ingano zingana na 85 mkm (Ishusho 3a); iyo igipimo cyo gukuramo ari 25, ibinyampeke bikururwa cyane, umubare wibinyampeke byongeye kwiyongera, kandi impuzandengo yintete igabanuka kugera kuri 71 mkm (Ishusho 3b); mugihe igipimo cyo gukuramo ari 39, usibye umubare muto wibinyampeke byahinduwe, microstructure igizwe ahanini nuburinganire bwongeye kugereranywa nubunini butaringaniye, hamwe nubunini bwikigereranyo kingana na 60 mkm (Ishusho 3c); iyo igipimo cyo gusohora ari 69, gahunda yo kongera imbaraga zisubirwamo zirangiye ahanini, ibinyampeke byumwimerere byahinduwe rwose mubinyampeke byubatswe kimwe, kandi impuzandengo yintete yatunganijwe igera kuri 41 mkm (Ishusho 3d); mugihe igipimo cyo gukuramo ari 156, hamwe niterambere ryuzuye ryibikorwa byo kongera imbaraga, microstructure irasa cyane, kandi ingano yingano yatunganijwe cyane kugeza kuri 32 mm (Ishusho 3e). Hamwe n'ubwiyongere bw'ikigereranyo cyo gukuramo, gahunda yo kongera gukora ibintu bigenda neza cyane, microstructure ya alloy iba imwe, kandi ingano y'ibinyampeke ikanonosorwa ku buryo bugaragara (Ishusho 3f).

Igishushanyo.3 Imiterere ya Metallografiya nubunini bwikigero cyigihe kirekire cya 6063 aluminium alloy inkoni hamwe nibipimo bitandukanye byo gukuramo

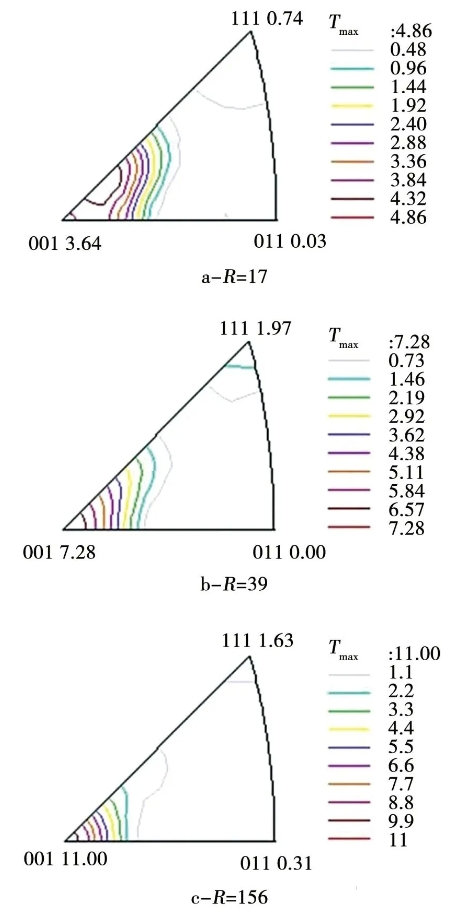

Igishushanyo cya 4 cyerekana ibishushanyo mbonera bya 6063 ya aluminiyumu ya aluminiyumu ifite ibipimo bitandukanye byo gukuramo icyerekezo cyo gusohora. Birashobora kugaragara ko microstructures ya alloy bar ifite ibipimo bitandukanye byo gukuramo byose bitanga icyerekezo kigaragara. Iyo igipimo cyo gukuramo ari 17, hashyizweho intege nke <115> + <100> (Ishusho 4a); iyo igipimo cyo gukuramo ari 39, ibice byimiterere nibyinshi bikomera <100> nuburyo buto bwintege nke <115> (Ishusho 4b); iyo igipimo cyo gukuramo ari 156, ibice bigize imyenda ni <100> imiterere hamwe nimbaraga ziyongereye cyane, mugihe <115> imiterere irazimira (Ishusho 4c). Ubushakashatsi bwerekanye ko kububiko bushingiye kumaso bushingiye cyane cyane muburyo bwa <111> na <100> insinga mugihe cyo gukuramo no gushushanya. Iyo imiterere imaze gushingwa, ubushyuhe bwicyumba ubukanishi bwimiterere ya alloy yerekana anisotropy igaragara. Imbaraga zimyenda ziyongera hamwe no kwiyongera kwikigereranyo cyo gukuramo, byerekana ko umubare wibinyampeke mubyerekezo bimwe na bimwe bya kristu ugereranije nicyerekezo cyo gusohora muri alloy ugenda wiyongera buhoro buhoro, kandi imbaraga ndende ndende ya aliyumu iriyongera. Uburyo bwo gushimangira ibikoresho 6063 bya aluminiyumu alloy ibikoresho bishyushye birimo gushimangira ingano nziza, gushimangira dislokasi, gushimangira imyenda, nibindi. Muburyo bwibipimo ngenderwaho bikoreshwa muri ubu bushakashatsi bwubushakashatsi, kongera igipimo cyo gukuramo bigira ingaruka nziza muburyo bwo gushimangira.

Igicapo.4 Igishushanyo mbonera cya pole ya 6063 ya aluminium alloy inkoni hamwe nibipimo bitandukanye byo gukuramo icyerekezo cyo gusohora;

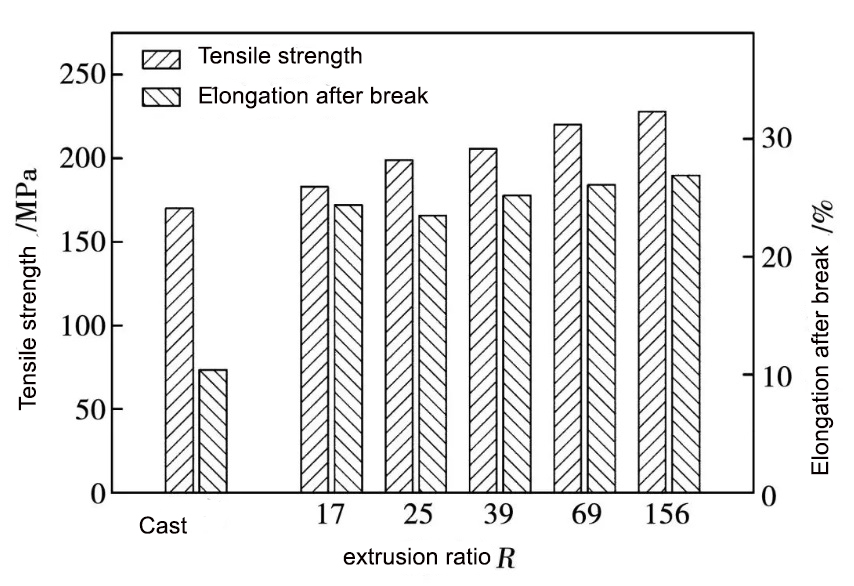

Igicapo 5 ni histogramu yimiterere ya tensile ya 6063 ya aluminiyumu nyuma yo guhindura ibintu muburyo butandukanye. Imbaraga zingana za cast alloy ni 170 MPa naho kurambura ni 10.4%. Imbaraga zingana no kurambura ibivanze nyuma yo gukuramo byateye imbere cyane, kandi imbaraga zingana no kuramba bigenda byiyongera buhoro buhoro hamwe no kwiyongera kwikigereranyo. Iyo igipimo cyo gukuramo ari 156, imbaraga zingana no kuramba kwa alloy bigera ku giciro ntarengwa, ni 228 MPa na 26.9%, ibyo bikaba bingana na 34% hejuru yimbaraga za tensile zivanze na 158% hejuru yo kuramba. Imbaraga zingana zingana na 6063 aluminium aluminiyumu yabonetse ku kigereranyo kinini cyo gukuramo ni hafi yingufu zingirakamaro (240 MPa) zabonywe na 4-pass zingana zingana zingana (ECAP), zikaba zisumba cyane agaciro kangana (171.1 MPa) zabonywe na 1-pass ECAP yo gukuramo 6063 ya aluminium. Birashobora kugaragara ko igipimo kinini cyo gukuramo gishobora kunoza imiterere yubukorikori ku rugero runaka.

Kuzamura imiterere yubukanishi bwa alloy ku kigereranyo cyo gukuramo biva ahanini mu gutunganya ingano. Mugihe igipimo cyo gukuramo cyiyongera, ingano zinonosowe kandi ubwinshi bwa dislocation bwiyongera. Imipaka myinshi yintete kuri buri gice irashobora kubangamira neza kwimuka kwa dislokisiyo, ihujwe no kwimuka no guhuzagurika, bityo bikazamura imbaraga zivanze. Ibinyampeke byiza, niko imbibi z’ibinyampeke zirushaho kuba nyinshi, hamwe n’imiterere ya plastiki irashobora gukwirakwizwa mu ngano nyinshi, ibyo bikaba bidafasha kurema ibice, tutibagiwe no gukwirakwiza ibice. Inguvu nyinshi zirashobora kwinjizwa mugihe co kuvunika, bityo bikazamura plastike yumuti.

Igicapo.5 Ibintu bya Tensile ya 6063 ya aluminiyumu nyuma yo guta no kuyikuramo

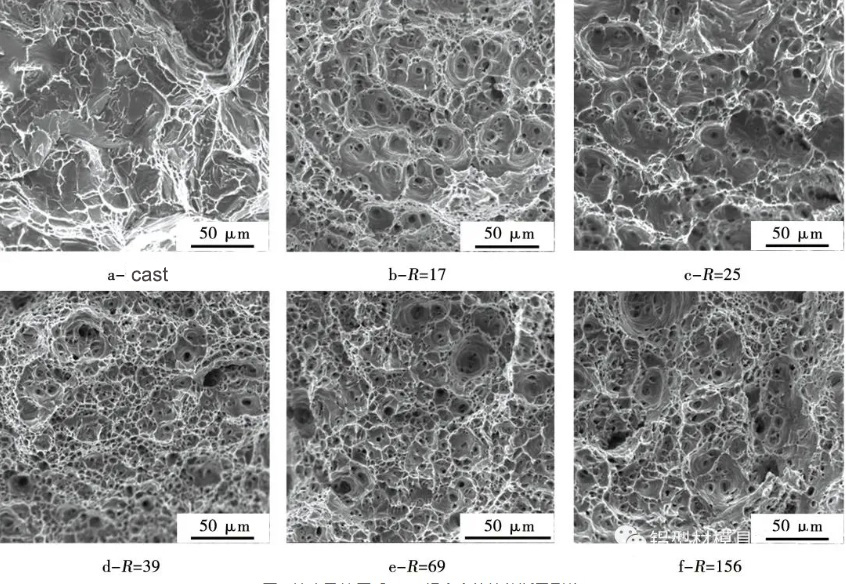

Igice cyavunitse cyimiterere ya alloy nyuma yo guhindagurika hamwe nigipimo gitandukanye cyo gusohora cyerekanwe ku gishushanyo cya 6. Nta dimimoni zabonetse muri morphologie yamenetse y’icyitegererezo (Ishusho ya 6a), kandi kuvunika kwari kugizwe ahanini n’ahantu hahanamye no ku nkombe zashwanyaguritse, byerekana ko uburyo bwavunitse bukabije bw’imvange zashizwemo ahanini. Ivunika rya morphologie ya alloy nyuma yo gukuramo ryahindutse ku buryo bugaragara, kandi kuvunika kugizwe numubare munini wibimera bingana, byerekana ko uburyo bwo kuvunika bwimvange nyuma yo kuyikuramo bwahindutse buvunika buvunika buvunika buvunika. Iyo igipimo cyo gukuramo ari gito, ibimera ni bito kandi ubunini bwa dimple ni bunini, kandi kugabana ntibingana; uko igipimo cyo gukuramo cyiyongera, umubare wibimera wiyongera, ubunini bwa dimple ni buto kandi kugabana ni kimwe (Igishusho 6b ~ f), bivuze ko ibivanze bifite plastike nziza, ibyo bikaba bihuye nibisubizo byubushakashatsi bwakozwe hejuru.

3 Umwanzuro

Muri ubu bushakashatsi, hasesenguwe ingaruka ziterwa n’ibicuruzwa bitandukanye kuri microstructure hamwe n’imiterere ya 6063 ya aluminiyumu ya aluminiyumu yasesenguwe hashingiwe ko ingano ya bilet, ubushyuhe bwo gushyushya ingot n'umuvuduko wo kuyikuramo bitigeze bihinduka. Imyanzuro niyi ikurikira:

1) Dynamic recrystallisation ibaho muri 6063 aluminiyumu mugihe cyo gukuramo ubushyuhe. Hamwe n'ubwiyongere bw'ikigereranyo cyo gukuramo, ibinyampeke bikomeza kunonosorwa, kandi ibinyampeke birambuye ku cyerekezo cyo gusohora bihinduka ibinyampeke byongeye gushyirwaho, kandi imbaraga za <100> insinga zikomeza kwiyongera.

2) Bitewe ningaruka zo gushimangira ingano nziza, imiterere yubukorikori bwa aliyumu iratera imbere hamwe no kwiyongera kwikigereranyo. Mubipimo byibizamini, mugihe igipimo cyo gukuramo ari 156, imbaraga zingana no kuramba kwa alloy bigera ku gipimo ntarengwa cya 228 MPa na 26.9%.

Igishushanyo.6 Imyivumbagatanyo ya morfologiya ya 6063 ya aluminiyumu nyuma yo guterwa no kuyisohora

3) Ivunika ryimiterere ya as-cast igizwe nibice bigororotse hamwe nimpande zamarira. Nyuma yo gukuramo, kuvunika bigizwe numubare munini wibimera bingana, kandi uburyo bwo kuvunika buhinduka kuva kuvunika kuvunika no kuvunika.

Igihe cyo kohereza: Ugushyingo-30-2024