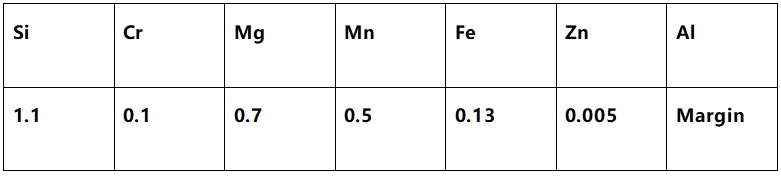

1

2. Inzira yo guhuza ibitsina

390 ℃ x izitera 1.0h + 575 ℃ x iziritse kuri 8h, umuyaga ukonje ukagera kuri 200 ℃ hanyuma ugakonjesha amazi.

3. Imiterere y'ibyuma

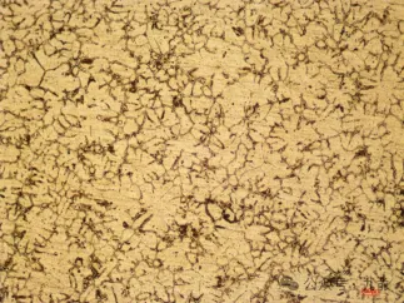

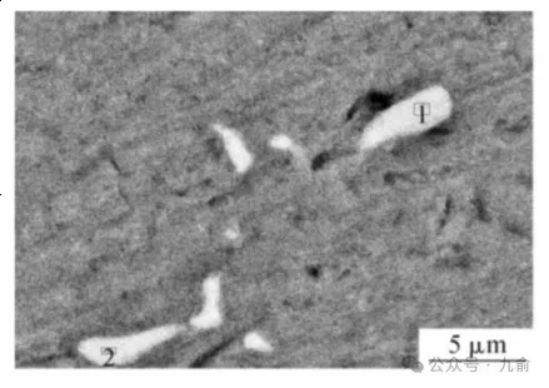

Igishushanyo 1 Imiterere yicyuma yibanze ya 6082 alloy ingot, yashizwemo na Keller reagent, hamwe na dendrite yateye imbere

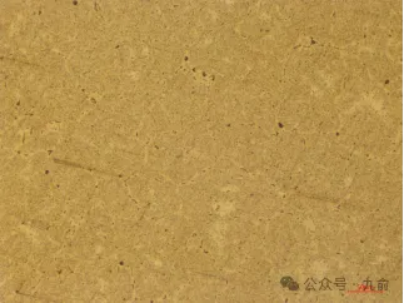

Igishushanyo cya 2 Metallographic structure of the core of 6082 alloy ingot, etched by Keller reagent, and structure after solution solution

4. Ingaruka zo kuvura ubushyuhe bwa homogenisation kumiterere ya alloy

4.1 Nkuko bigaragara ku gishushanyo cya 1, ibinyomoro bifite dendrite yateye imbere muri reta yabakinnyi, kandi hariho umubare munini wurusobe rwimvura idahwanye nimbibi zimbibi.

4.2 Kubera ko ingingo zo gushonga yibintu bitandukanye ziratandukanye iyo ibinyomoro bikomye, iki kintu gikurikiranye gikurikirana kiganisha ku guhuza ibice bitaringaniye muri kristu, bigaragarira cyane cyane kubyara ibisekuru byinshi byimvura igwa kumupaka wimbuto.

4.3 Muri microstructure nyuma yo kuvura homogenisation (Igicapo 2), ingano yicyiciro cyimvura kumupaka wingano iragabanuka cyane, kandi ingano yiyongera icyarimwe. Ni ukubera ko ikwirakwizwa rya atome ryongerewe imbaraga mu bushyuhe bwo hejuru, kurandura amacakubiri no gusesa icyiciro kitaringaniye bibaho muri ingot, kandi imiyoboro y'urusobe ku mbibi z'ingano irashonga igice.

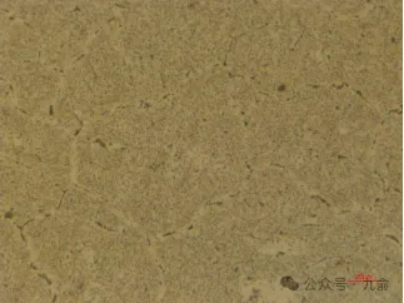

4.4 Binyuze mu isesengura rya SEM, nkuko bigaragara muri FIG3, ibice bitandukanye byicyiciro cyimvura byatoranijwe kugirango bisesengurwe EDS, byemeza ko icyiciro cyimvura cyari Al (MnFe) Si icyiciro.

4.5 Mugihe cyo guta amavuta, hashyizweho igice kinini cya Mn kirimo imvura igwa, kandi igice cyacyo kigumana igisubizo gikomeye. Nyuma yubushyuhe bwo hejuru hamwe nigihe kirekire cyo kuvura homogenisation, Mn irenze urugero muri matrix igwa muburyo bwimvange ya Mn, ibyo bikaba bigaragazwa nkumubare munini watatanye Mn urimo ibice byangirika byangirika muri kristu (Ishusho 2).

4.6 Kubera ko icyiciro cyimvura kirimo Mn element, gifite ubushyuhe bwiza bwumuriro. Hamwe no gukaza umurego wo gukwirakwiza atome, ibice bya Al (MnFe) Si byerekana buhoro buhoro ibimenyetso biranga spheroidisation.

Igishushanyo.3 Al (MnFe) Si icyiciro cya 6082

5. Ingaruka yumuti usaza kumiterere yimashini

Nyuma yo guhuza ibitsina, urusobe rwaguye icyiciro cyambere kumupaka wimbuto za 6082 zivanze zirashonga, zishobora kunoza imiterere yubukorikori. Muri icyo gihe, icyiciro gihamye cyihanganira ubushyuhe Al (MnFe) Si icyiciro cyarushijeho kuba spheroidised, gishobora kuba cyiza pin dislocations. Ibi birerekana ko imikorere yuzuye yibikoresho izanozwa nyuma yo kuvura ubushyuhe bwa homogenisation.

6. Umwanzuro

6.1 6082 ya aluminium alloy ingot ifite dendrite yateye imbere neza hamwe numubare munini wurusobe rutagabanije imvura igwa kumupaka wingano.

6.2 Nyuma yo kuvura homogenisation, ubushakashatsi bwakozwe na microscopique bwerekanye ko ingano yimvura yagabanutse cyane, kandi ingano yiyongereye icyarimwe. Kurandura amacakubiri no gusesa icyiciro kitaringaniye byabaye muri ingot, kandi imiyoboro y'urusobe ku mbibi z'ingano zaseswa igice.

6.3 Iyo utera 6082 alloy, Al (MnFe) Si imvura igwa. Icyiciro cyimvura kirimo ibintu bya Mn kandi bifite ubushyuhe bwiza bwumuriro. Mugihe gahunda yo guhuza ibitsina ikomeza, ibice byimvura bigenda byerekana buhoro buhoro ibiranga spheroidisation. Iyi Mn irimo ibice bigize ibice bitatanye kimwe kandi bigwa muri kristu.

6.4 Nyuma yo kuvura homogenisation, iseswa ryurwego rwimvura yaguye byerekana ko imikorere rusange ya ingot yose itezimbere nyuma yo kuvura ubushyuhe bwa homogenisation.

Igihe cyo kohereza: Jun-08-2025