Mugihe cyo gukuramo ibikoresho bya aluminiyumu ivanze ibikoresho, cyane cyane imyirondoro ya aluminium, inenge ya "piting" ikunze kugaragara hejuru. Ibigaragara byihariye birimo ibibyimba bito cyane bifite ubucucike butandukanye, umurizo, hamwe nintoki zigaragara, hamwe numutima wuzuye. Nyuma ya okiside cyangwa amashanyarazi ya elegitoronike, akenshi bigaragara nka granules yumukara ifata hejuru yibicuruzwa.

Mu musaruro wo gukuramo imyirondoro minini, iyi nenge irashobora kugaragara cyane bitewe ningaruka yimiterere ya ingot, ubushyuhe bwo gukuramo ibicuruzwa, umuvuduko wo gukuramo ibicuruzwa, ibintu bigoye cyane, nibindi byinshi. Ibice byinshi byiza byinenge byashizwemo birashobora gukurwaho mugihe cyo kwitegura kwishusho yimbere, cyane cyane inzira ya alkali, mugihe umubare muto wibintu binini, bifatanye neza bikomeza kugaragara kumiterere yumwirondoro, bikagira ingaruka kumiterere yanyuma.

Mubisanzwe byubaka urugi nidirishya ryibicuruzwa, abakiriya muri rusange bemera utunenge duto duto, ariko kubirangantego byinganda bisaba gushimangira kimwe kumitungo yubukorikori no gukora imitako cyangwa gushimangira cyane imikorere yimitako, abakiriya muri rusange ntibemera iyi nenge, cyane cyane inenge yashizwemo idahuye nibara ritandukanye.

Kugirango dusesengure uburyo bwo gukora uduce duto duto, morphologie hamwe nibigize ahantu hafite inenge hifashishijwe ibihimbano bitandukanye hamwe nuburyo bwo gusohora, hasesenguwe itandukaniro riri hagati yinenge na matrix. Igisubizo cyumvikana cyo gukemura neza ibice bitoroshye cyashyizwe imbere, kandi hakozwe ikizamini cyo kugerageza.

Kugira ngo ukemure inenge ya profitingi, birakenewe gusobanukirwa uburyo bwo gushiraho inenge. Mugihe cyo gukuramo, aluminiyumu yiziritse kumukandara wakazi niyo ntandaro nyamukuru yo gutera inenge hejuru yibikoresho bya aluminiyumu. Ni ukubera ko inzira yo gukuramo aluminiyumu ikorwa ku bushyuhe bwo hejuru bwa 450 ° C. Niba ingaruka zubushyuhe bwa deformasiyo hamwe nubushyuhe bwo guterana byongeweho, ubushyuhe bwicyuma buzaba bwinshi iyo busohotse mu mwobo. Iyo ibicuruzwa bisohotse mu mwobo upfa, kubera ubushyuhe bwinshi, habaho phenomenon ya aluminiyumu ifatanye hagati yicyuma n'umukandara ukora.

Imiterere yu guhuza akenshi: inzira isubirwamo yo guhuza - gutanyagura - guhuza - kongera gushwanyagurika, kandi ibicuruzwa bitembera imbere, bikavamo ibyobo byinshi bito hejuru yibicuruzwa.

Ibi bintu bifitanye isano nibintu nkubwiza bwa ingot, imiterere yubuso bwumukandara ukora, ubushyuhe bwo gusohora, umuvuduko wo gusohora, urugero rwo guhindura ibintu, hamwe no kurwanya ibyuma.

1 Ibikoresho byo gupima nuburyo

Binyuze mu bushakashatsi bwibanze, twamenye ko ibintu nkubuziranenge bwibyuma, imiterere yimiterere, uburyo bwo kuvoma, ibiyigize, hamwe nuburyo bwo kubyara bishobora kugira ingaruka kubutaka bubi. Mu kizamini, inkoni ebyiri zivanze, 6005A na 6060, zakoreshejwe mu gusohora igice kimwe. Imiterere ya morphologie hamwe nibigize imyanya igoye yasesenguwe hakoreshejwe uburyo bwo gusoma butaziguye hamwe nuburyo bwo gutahura SEM, kandi ugereranije na matrise isanzwe ikikije.

Kugirango tumenye neza morphologie yinenge ebyiri zashizwemo nuduce, zisobanuwe kuburyo bukurikira:

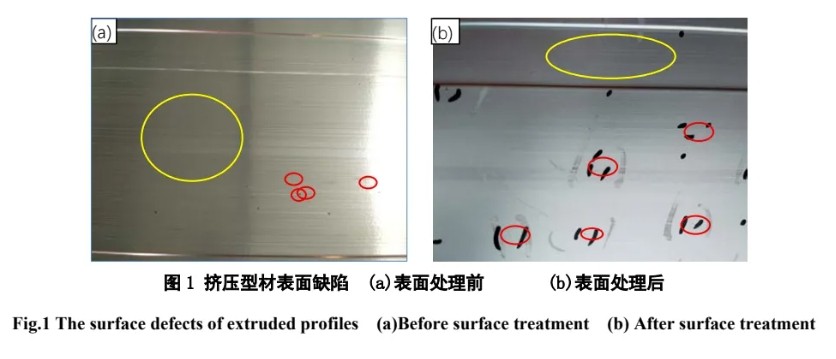

. Inenge itangirira kumurongo wa scratch ikarangira inenge iguye, ikegeranya mubishyimbo byicyuma kumpera yumurongo. Ingano yinenge yashizwemo muri rusange ni 1-5mm, kandi ihinduka umukara wijimye nyuma yo kuvura okiside, amaherezo ikagira ingaruka kumiterere yumwirondoro, nkuko bigaragara mumuzingi utukura ku gishushanyo 1.

(2) Ibice byo hejuru nabyo byitwa ibishyimbo byibyuma cyangwa adsorption. Ubuso bwa aluminium alloy umwirondoro uhujwe na serefegitura yumukara-umukara wicyuma gikomeye kandi gifite imiterere idakabije. Hariho ubwoko bubiri bwa aluminiyumu yumwirondoro: ibishobora guhanagurwa nibidashobora guhanagurwa. Ingano muri rusange iri munsi ya 0.5mm, kandi irumva itoroshye gukoraho. Nta gishushanyo kiri mu gice cy'imbere. Nyuma ya okiside, ntabwo itandukanye cyane na matrix, nkuko bigaragara muruziga rw'umuhondo ku gishushanyo 1.

2 Ibisubizo n'ibizamini

2.1 Gukurura ubuso

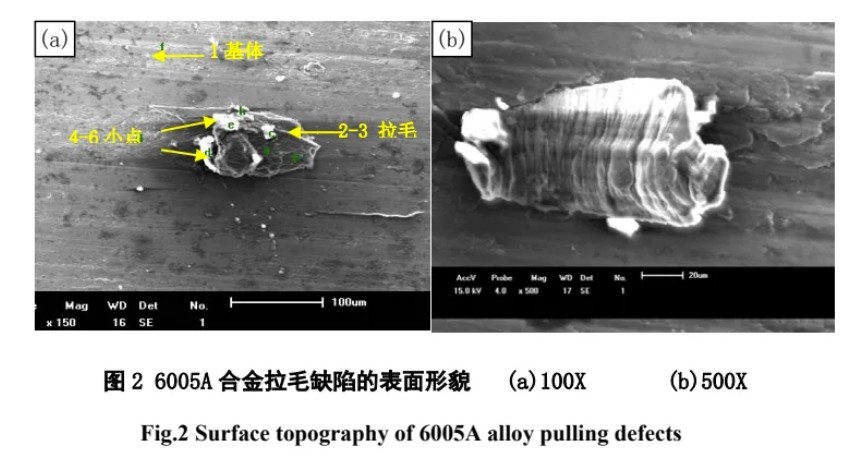

Igishushanyo cya 2 cyerekana microstructural morphologie yinenge ikurura hejuru yumuti wa 6005A. Hano hari intambwe isa nintambwe mugice cyimbere cyo gukurura, kandi birangirana na node. Nyuma ya nodules igaragara, ubuso busubira mubisanzwe. Ahantu h'inenge itoroshye ntabwo yoroshye gukoraho, ifite ibyiyumvo bikaze, kandi ikomera cyangwa ikarundanya hejuru yumwirondoro. Binyuze mu kizamini cyo gukuramo, byagaragaye ko gukurura morphologie ya 6005A na 6060 imyirondoro yakuwe bisa, kandi umurizo wibicuruzwa birenze imitwe yumutwe; itandukaniro nuko ubunini bukurura bwa 6005A ari buto kandi ubujyakuzimu bugabanuka. Ibi birashobora kuba bifitanye isano nimpinduka mubihimbano, inkoni imiterere, hamwe nuburyo bumeze. Urebye munsi ya 100X, hari ibimenyetso bigaragara byerekana ku mpera yimbere yikibanza gikurura, kikaba kirambuye ku cyerekezo cyo gusohora, kandi imiterere yibice byanyuma bya nodule ntibisanzwe. Kuri 500X, impera yimbere yikururwa rifite intambwe isa nintambwe ku cyerekezo cyo gusohora (ingano yiyi nenge igera kuri 120 mkm), kandi hariho ibimenyetso bigaragara byerekana uduce duto twa node ku mpera yumurizo.

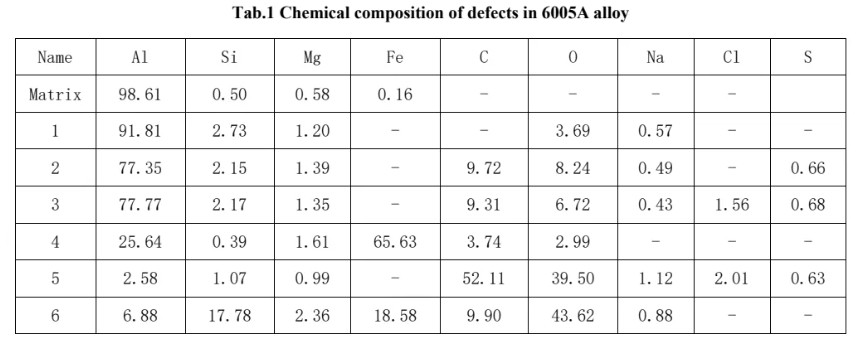

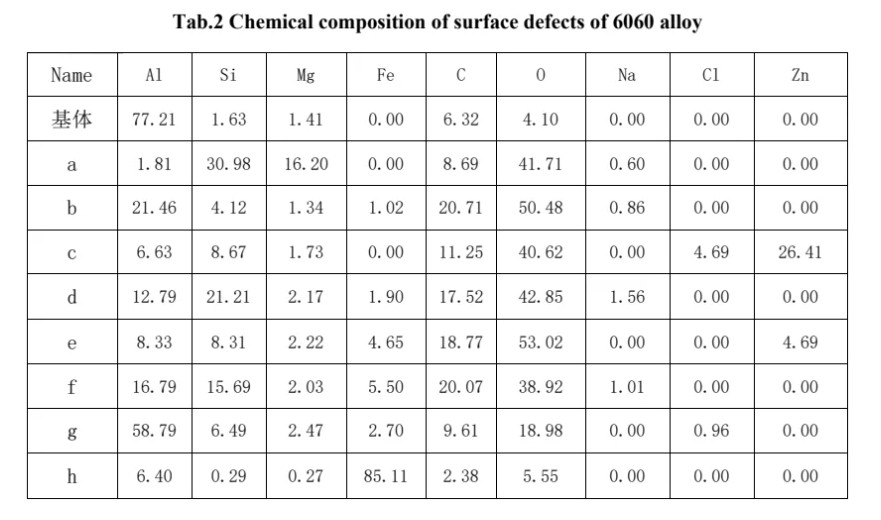

Kugirango dusesengure ibitera gukurura, hifashishijwe gusoma bitaziguye na EDX byakoreshejwe kugirango hakorwe isesengura ryibice ahantu hafite inenge na matrix yibice bitatu bivanze. Imbonerahamwe 1 irerekana ibisubizo byikizamini cya 6005A. Ibisubizo bya EDX byerekana ko ibigize umwanya wo gutondekanya ibice bikurura bisa nkibya matrix. Mubyongeyeho, uduce tumwe na tumwe twanduye twirundanyirijwe hamwe no gukurura inenge, kandi ibice byanduye birimo C, O (cyangwa Cl), cyangwa Fe, Si, na S.

Isesengura ryinenge zikaze za 6005A imyirondoro myiza ya okiside yerekana neza yerekana ko ibice bikurura ari binini mubunini (1-5mm), ubuso burashyizwe hamwe, kandi hariho ibishushanyo bisa nintambwe ku gice cyimbere; Ibigize byegeranye na Al matrix, kandi hazaba ibyiciro bitandukanye birimo Fe, Si, C, na O bikwirakwijwe hafi yacyo. Irerekana ko uburyo bwo gukurura uburyo bwo gukurura ibice bitatu ari bimwe.

Mugihe cyo gusohora, guteranya ibyuma bizatera ubushyuhe bwumukandara wumukandara kuzamuka, bigakora "aluminiyumu yumuti" kumpera yumuryango wumukandara. Muri icyo gihe, ibirenze Si nibindi bintu nka Mn na Cr muri aluminiyumu byoroshye biroroshye gushiraho ibisubizo bikomeye hamwe na Fe, bizateza imbere ishyirwaho rya "aluminiyumu yumuti" ku bwinjiriro bwa zone ikora.

Mugihe icyuma gitemba imbere kandi kikanyerera ku mukandara wakazi, ibintu bisubiranamo byo gukomeza guhuza-gutanyagura-guhuza bibaho ahantu runaka, bigatuma icyuma gikomeza kurenga kuriyi myanya. Iyo ibice byiyongereye kugeza mubunini runaka, Bizakururwa nibicuruzwa bitemba hanyuma bikore ibimenyetso bishushanyije hejuru yicyuma. Bizaguma hejuru yicyuma hanyuma bikuremo ibice bikurura impera. kubwibyo, dushobora gutekereza ko kwibumbira mu bice bifitanye isano ahanini na aluminiyumu ifatanye n'umukandara ukora. Ibyiciro bya heterogeneous byakwirakwijwe hirya no hino bishobora guturuka kumavuta yo gusiga, okiside cyangwa uduce twumukungugu, hamwe numwanda uzanwa nubuso bwa ingot.

Nyamara, umubare wikurura muri 6005A ibisubizo byikizamini ni muto kandi impamyabumenyi iroroshye. Ku ruhande rumwe, biterwa no gutombora gusohoka k'umukandara ukora no guhanagura neza umukandara ukora kugirango ugabanye umubyimba wa aluminium; kurundi ruhande, bifitanye isano nibirimo Si birenze.

Ukurikije ibisubizo bitaziguye byo gusoma byerekana, birashobora kugaragara ko usibye Si uhujwe na Mg Mg2Si, Si isigaye igaragara muburyo bwibintu byoroshye.

2.2 Uduce duto hejuru

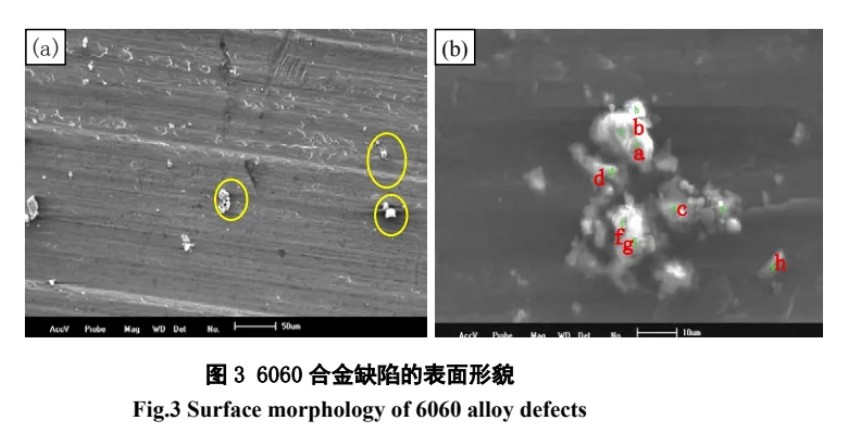

Mugihe cyo kugenzura gukabije kugaragara, ibice ni bito (≤0.5mm), ntabwo byoroshye gukoraho, bifite ibyiyumvo bikarishye, kandi bifatanye hejuru yumwirondoro. Urebye munsi ya 100X, uduce duto hejuru hejuru twakwirakwijwe ku bushake, kandi hari uduce duto duto twafatanyirijwe hejuru tutitaye ko hari ibishushanyo cyangwa bidahari;

Kuri 500X, uko byagenda kose niba hari intambwe igaragara nkintambwe igaragara hejuru yicyerekezo cyo gusohora, ibice byinshi biracyafatanye, kandi ingano yingingo ziratandukanye. Ingano nini nini ni 15 mkm, naho uduce duto tugera kuri 5 mm.

Binyuze mu isesengura ryakozwe rya 6060 alloy surface ibice hamwe na matrix idahwitse, ibice bigizwe ahanini na O, C, Si, na Fe, kandi aluminium iri hasi cyane. Hafi ibice byose birimo O na C. Ibigize buri gice kiratandukanye gato. Muri byo, ibice bigera kuri 10 mkm, bikaba hejuru cyane ugereranije na matrix Si, Mg, na O; Muri c ibice, Si, O, na Cl biragaragara ko biri hejuru; Ibice d na f birimo Si, O, na Na; ibice e birimo Si, Fe, na O; h ibice ni Fe-irimo ibice. Ibisubizo by'ibice 6060 bisa nibi, ariko kubera ko ibirimo Si na Fe muri 6060 ubwabyo biri hasi, ibirimo bihuye na Si na Fe mubice byo hejuru nabyo biri hasi; ibirimo C mubice 6060 ni bike.

Ibice byo hejuru ntibishobora kuba bito bito, ariko birashobora no kubaho muburyo bwo guteranya uduce duto duto dufite imiterere itandukanye, kandi ubwinshi bwijanisha ryibintu bitandukanye mubice bitandukanye biratandukanye. Byizerwa ko ibice bigizwe ahanini nubwoko bubiri. Imwe muriyo ni imvura nka AlFeSi na Si yibanze, ikomoka kumurongo wo hejuru ushonga ibyiciro byanduye nka FeAl3 cyangwa AlFeSi (Mn) muri ingot, cyangwa ibyiciro byimvura mugihe cyo gukuramo. Ibindi ni umuyoboke w'amahanga.

2.3 Ingaruka zubuso bwa ingot

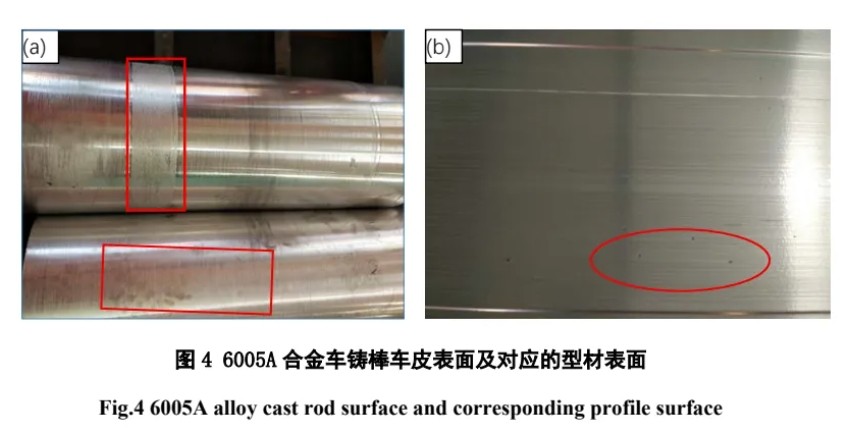

Mu gihe cy’ibizamini, byagaragaye ko hejuru yinyuma yumusarani wa 6005A washyizwemo umukungugu kandi wuzuye umukungugu. Hariho inkoni ebyiri zashizweho zifite ibimenyetso byimbitse byerekana ibikoresho byaho, ibyo bikaba byari bihuye nubwiyongere bugaragara bwumubare wikururwa nyuma yo gusohora, kandi ubunini bwikurura rimwe bwari bunini, nkuko bigaragara ku gishushanyo 7.

Inkoni ya 6005A idafite umusarani, bityo uburinganire bwubuso buri hasi kandi umubare wikurura uragabanuka. Mubyongeyeho, kubera ko nta mazi arenze yo gukata yometse ku musarani winkoni yinkoni, ibirimo C mubice bihuye bigabanuka. Byaragaragaye ko ibimenyetso bihinduka hejuru yinkoni yinkoni bizongera gukurura no gukora uduce duto kurwego runaka.

3 Ikiganiro

(1) Ibigize gukurura inenge ahanini ni bimwe na matrix. Nibice byamahanga, uruhu rushaje hejuru ya ingot nibindi byanduye byegeranijwe murukuta rwa barrale cyangwa ahantu hapfuye hacuramye mugihe cyo gukuramo, bizanwa hejuru yicyuma cyangwa aluminiyumu yumukandara ukora. Mugihe ibicuruzwa bitembera imbere, gushushanya hejuru biraterwa, kandi mugihe ibicuruzwa byegeranije mubunini runaka, bikurwa mubicuruzwa kugirango bikurure. Nyuma ya okiside, gukurura byarangiritse, kandi kubera ubunini bwayo, hariyo inenge zimeze nk'urwobo.

(2) Ibice by'ubuso rimwe na rimwe bigaragara nkibice bito bito, kandi rimwe na rimwe bibaho muburyo rusange. Ibihimbano byabo biragaragara ko bitandukanye cyane na matrix, kandi ahanini birimo O, C, Fe, na Si. Bimwe mubice byiganjemo O na C, naho ibice bimwe byiganjemo O, C, Fe, na Si. Kubwibyo, hafatwa umwanzuro ko ibice byubuso biva mubisoko bibiri: kimwe ni imvura nka AlFeSi na Si element element, kandi umwanda nka O na C ufatirwa hejuru; Ibindi ni umuyoboke w'amahanga. Ibice byangirika nyuma ya okiside. Bitewe nubunini bwazo, nta ngaruka cyangwa nkeya bigira hejuru.

. Ibice byingenzi bigize amavuta yo gusiga ni C, O, H, S, nibindi, kandi igice kinini cyumukungugu nubutaka ni SiO2. O ibice bigize ubuso buri hejuru. Kuberako ibice biri mubushyuhe bwo hejuru ako kanya nyuma yo kuva mukenyero wakazi, kandi bitewe nubuso bunini bwubuso bwibice, bahita borohereza atome O mu kirere kandi bigatera okiside nyuma yo guhura nikirere, bikavamo ibintu byinshi O birenze matrix.

(4) Fe, Si, etc. Ikintu cya Fe gikomoka kuri Fe mubikoresho bya aluminiyumu, bigakora ibyiciro byinshi byo gushonga byanduye nka FeAl3 cyangwa AlFeSi (Mn), bidashobora gushonga mubisubizo bikomeye mugihe cyo guhuza ibitsina, cyangwa bidahinduwe neza; Si ibaho muri matrix ya aluminium muburyo bwa Mg2Si cyangwa igisubizo gikomeye cya Si mugihe cyo gukina. Mugihe cyo gushyushya ibintu bishyushye byinkoni, Si irenze irashobora kugwa. Ubushyuhe bwa Si muri aluminium ni 0.48% kuri 450 ° C na 0.8% (wt%) kuri 500 ° C. Ibirenga Si birenze muri 6005 ni 0.41%, kandi Si imvura irashobora kuba igiteranyo hamwe nimvura biterwa nihindagurika ryimiterere.

(5) Aluminium ifatanye n'umukandara ukora ni yo mpamvu nyamukuru yo gukurura. Gusohora bipfa ni ubushyuhe bwo hejuru hamwe n’umuvuduko mwinshi. Guterana kwicyuma bizamura ubushyuhe bwumukandara wakazi wububiko, bikore "igikoresho cya aluminiyumu gifatika" kumpera yumuryango wumukandara.

Muri icyo gihe, ibirenze Si nibindi bintu nka Mn na Cr muri aluminiyumu byoroshye biroroshye gushiraho ibisubizo bikomeye hamwe na Fe, bizateza imbere ishyirwaho rya "aluminiyumu yumuti" ku bwinjiriro bwa zone ikora. Icyuma gitembera muri "layer aluminium layer" ni iy'imbere yo guterana imbere (kogosha kunyerera imbere mu cyuma). Icyuma kirahinduka kandi kigakomera kubera guterana imbere, biteza imbere icyuma cyimbere hamwe nububiko kugirango bifatanye. Muri icyo gihe, umukandara ukora wibumba uhindurwa muburyo bwo kuvuza impanda kubera umuvuduko, kandi aluminiyumu ifatanye ikozwe nigice cyo gukata igice cyumukandara ukora ihuza umwirondoro isa no guca ku gikoresho cyo guhindura.

Gukora aluminiyumu ifatika ni inzira ikomeye yo gukura no kumeneka. Ibice bihora bizanwa numwirondoro.Ahantu hejuru yumwirondoro, bikora inenge zikurura. Niba isohotse mu buryo butaziguye umukandara wakazi hanyuma igahita imenyekana hejuru yumwirondoro, utuntu duto duto twafatanywe nubushuhe bwitwa "adsorption particles". Niba uduce tumwe na tumwe tuzavunwa na aluminiyumu yasohotse, ibice bimwe bizaguma hejuru yumukandara wakazi iyo unyuze mumukandara wakazi, bigatera ibishushanyo hejuru yumwirondoro. Umurizo wumurizo ni materique ya aluminiyumu. Iyo hari aluminiyumu nyinshi yometse hagati yumukandara wakazi (umurunga urakomeye), bizamura ibishushanyo mbonera.

(6) Umuvuduko wo gukuramo ufite uruhare runini mugukurura. Ingaruka zo kwihuta. Kubijyanye na 6005 alloy ikurikiranwa, umuvuduko wo gusohora wiyongera murwego rwo kwipimisha, ubushyuhe bwo gusohoka buriyongera, kandi umubare wibice bikurura hejuru byiyongera kandi bikaremerwa uko imirongo yubukanishi yiyongera. Umuvuduko wo gukuramo ugomba guhora uhagaze neza bishoboka kugirango wirinde impinduka zitunguranye mumuvuduko. Umuvuduko ukabije wubushyuhe hamwe nubushyuhe bwo hejuru buzatuma habaho kwiyongera no gukurura ibice bikomeye. Uburyo bwihariye bwingaruka zumuvuduko wo gukuramo ibintu bikurura bisaba gukurikiranwa no kugenzura.

(7) Ubwiza bwubuso bwinkoni yabugenewe nabwo ni ikintu cyingenzi kigira ingaruka ku gukurura ibice. Ubuso bwinkoni yabakonje burakomeye, hamwe no kubona burr, irangi ryamavuta, ivumbi, ruswa, nibindi, byose byongera imyumvire yo gukurura ibice.

4 Umwanzuro

(1) Ibigize gukurura inenge bihuye nibya matrix; ibigize ibice byumwanya bigaragara ko bitandukanye cyane na matrix, cyane cyane irimo O, C, Fe, na Si.

(2) Gukurura inenge ziterwa ahanini na aluminiyumu ifatanye n'umukandara ukora. Ibintu byose biteza imbere aluminiyumu kwizirika kumukandara ukora bizatera gukurura inenge. Hashingiwe ku kwemeza ubuziranenge bw'inkoni, ibisekuru byo gukurura ibice nta ngaruka bigira ku bigize ibivangwa.

(3) Kuvura neza umuriro ni byiza kugabanya gukurura hejuru.

Igihe cyo kohereza: Nzeri-10-2024